Programmable Munitions: Projectiles ‘Evolved’ For The Modern Era

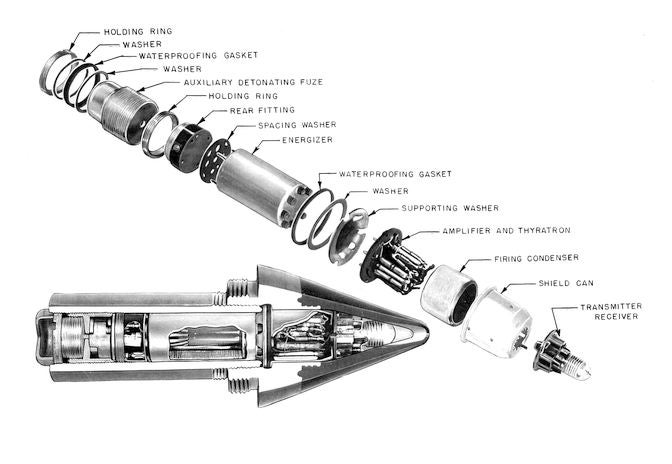

Ever since Henry Shrapnel invented the Shrapnel shell in the early 1800s, gunners have been looking for ways to control when and how their projectiles detonate downrange. For most of history, this was accomplished with mechanical fuses which were either set by hand or by automatic fuse setting machines.

The advent of cheap, miniaturised electronics have allowed munitions to be rapidly programmed in the breech, while being loaded, or while being fired. This has brought programming capability to smaller, faster firing weapons than was previously possible. While this development is more “evolutionary” than “revolutionary”, it could greatly increase lethality of direct fire support in ground combat.

While there are many types of programmable munitions, the primary purpose of most programmable munitions is to airburst at a specific distance from a target. For infantry targets, airbursts are often more effective than direct impacts, as the distribution of a fragmentation pattern is more effective when it’s radiating from a point in the air, rather than a point in the ground.

This has long been known to artillery gunners, who have used airburst shells in some form or another for over 200 years. But artillerymen have the luxury of being able to set their timed or proximity fuses ahead of time, often prepping entire batches to airburst during a barrage. For direct-fire cannon shooting in a relatively low arcs at soft targets, proximity-to-ground fuses are less useful, and hand set time fuses could be too slow for a direct-fire engagement.

Laser rangefinders combined with electronic fuses present a fast solution to this problem. A system can determine the range of a target to airburst, and then set the electronic fuse to detonate the round at the proper distance. Electronic fuses and laser rangefinders are largely uniform in their implementation across programmable munitions. Where systems differ is in setting the electronic fuse reliably.

One of the most simple ways to program a projectile is through electrical contacts in the chamber or breech of the gun. This solution is reliable and simple, but often requires a clean slate design or significant redesigning of the ammunition or gun to work properly. A gun’s chamber is often engineered to withstand very high pressures generated during the firing. Boring holes to add electrical contacts may compromise the integrity of the chamber, so this method is almost never seen on airburst systems retrofitted on existing guns.

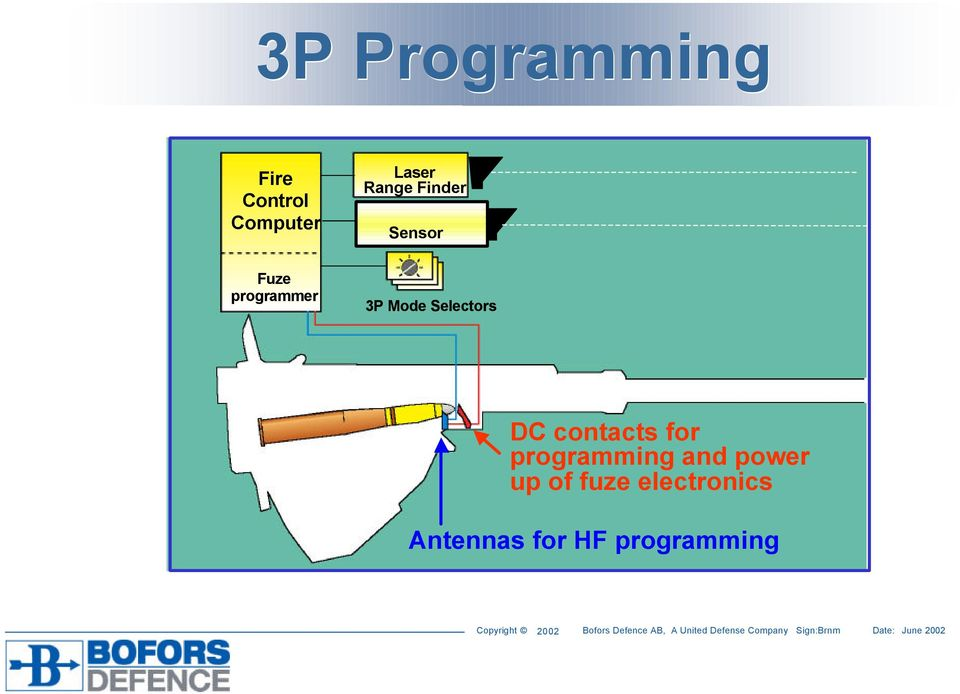

Guns designed to fire programmable ammunition from scratch largely have gone with the chamber contact approach though. The latest version of the Swedish Bofors 40mm autocannon with programming capability utilizes direct current contacts in the chamber to initialize the round and program information into them.

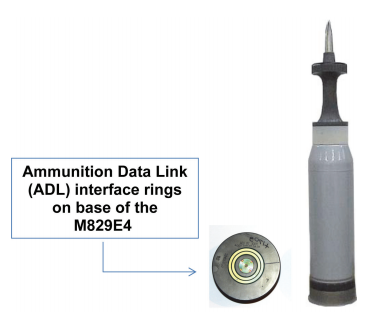

Alternatively, contacts can be placed on the breech face of a gun to interface with contacts on the base of a round, but that requires re-engineering the entire round to send data through the entire round to the fuze in the nose. This approach has been used in several 120mm NATO tank rounds, such as the DM11 multipurpose high explosive projectile and the new M829A4 armor-piercing projectile.

But this only works because NATO tank rounds are single piece. Two-piece tank rounds are unable to use breech contacts, as their ammo is generally loaded in two stages, and trying to establish consistent contact between the propellant and the projectile would likely prove problematic.

To solve this, Russia, the largest user of two-piece tank ammunition in the world, programs ammunition during the loading phase. “Ainet”, the Russian airburst system, uses a special electronic fuse fitted on existing high explosive fragmentation shells. This fuse is programmed by electrical contacts during the autoloader’s loading cycle before it’s loaded into the gun. While simple, this system means that the fuse cannot be reprogrammed once inserted into the breech. Any shots taken by Ainet will be with the fuse setting at time of loading, not at time of firing.

What About Wireless?

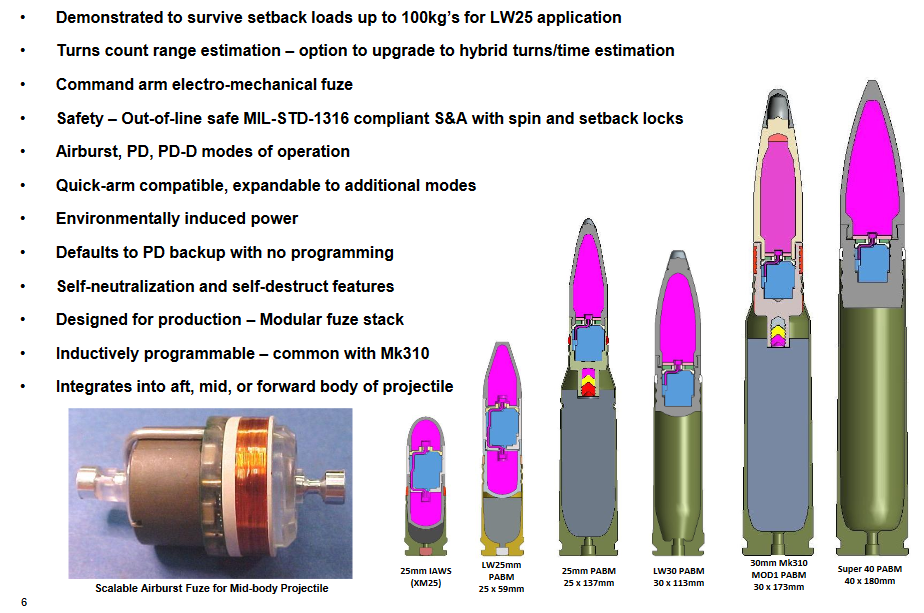

All of these solutions, however, use direct electrical contact. Wireless approaches give increased flexibility to where and when rounds are programmed, at the cost of increased complexity. One wireless approach uses a coil in the feed system to induce current in a coil in the projectile, programming the round. This coil approach is favored by Orbital ATK, the producer of most autocannon ammunition used by the US military. Orbital ATK developed a common coil-programmed airburst fuse that is shared across all its ammunition types, from the tiny 25mm cartridge used in the cancelled XM25 “Punisher” to massive “Super 40” 40mm rounds for the 40mm Bushmaster. This technology is used on the airburst-capable Mk44 30mm Bushmaster used on the Stryker Dragoon.

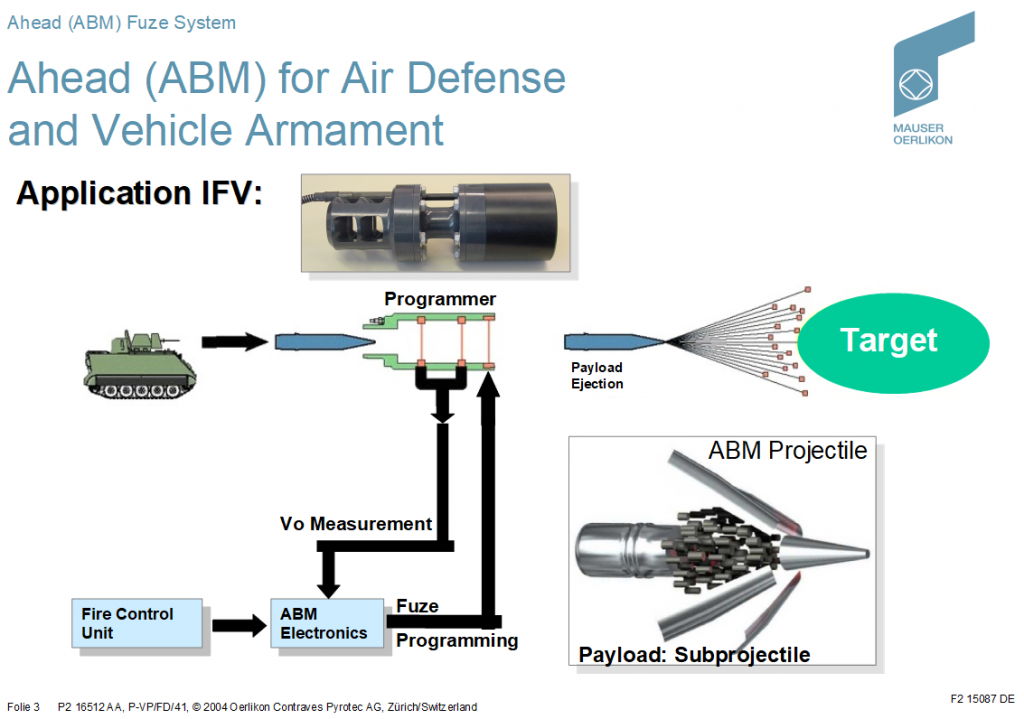

A similar coil system appears to equip the new British-French CT40 cased-telescopic autocannon, albeit with a coil around the barrel to program the round as it’s leaving the barrel. Oerlikon’s new 35mm autocannons take this to the next level, with a special velocity sensor past the muzzle brake that measures the velocity of the round as it is leaving the barrel. A programming coil then programs the round based on that velocity. This module is used in conjunction with their new AHEAD 35mm fragmenting rounds.

However, these coil systems have a competitors in new optically programmed systems. Promising to be simpler and easier to retrofit, optically programmed airburst works by using coded pulses of infrared light to program a round after it leaves the barrel. This means only a new projectile is needed, and the feed, barrel, and breech can be used unaltered. Rheinmetall developed the first fielded example of this system with their “Vingmate” fire control system paired with the DM131 round. This was adopted by the Bundeswehr to give airburst capability to their 40x53mm H&K GMG automatic grenade launchers. A similar system was awarded a development contract by the US Army to develop an alternative to Orbital’s coil system for medium calibre autocannons, but has yet to seen fruition.

Another approach is programming via regular radio transmissions, which is used on Nammo’s HEDP-RF 40x53mm airburst ammunition. While the Nammo round is probably readily compatible with existing grenade launchers, like Rheinmetall’s optical system, the miniature radio receiver in each round is probably very expensive.

Where Does The Future Lie?

Of all these approaches, all have advantages and potential problems. Contacts directly in the gun are the most reliable, but require a complete rework of the gun. Orbital’s coil system and Ainet are both relatively unjammable and simple to retrofit, but the round cannot be reprogrammed once loaded. Oerlikon’s barrel programmer is very precise and well suited to anti-aircraft applications, but rough use on IFVs may damage the barrel programmer. Rheinmetall’s optical programming works, but could be blocked if mud is thrown on the optical transmitter by an explosion, or if the ammunition gets dirty. Nammo’s solution is probably expensive, and could be hindered by electronic warfare on the battlefield.

But the myriad of solutions is proof that programmable munitions are here to stay and there is tons of demand for them. While airbursting at a specific distance is the most common goal of programming a munition, there are tons of other capabilities that programming can bring. Bofors makes a multi-mode programmable proximity fuse for some 40mm ammunition, with different fusing modes depending on what kind of target is being engaged. Other projectiles can be programmed with a delayed detonation to burrow into materials before detonating for maximum damage.

Munitions can be “programmed” even without computers. While not as complex as most other systems discussed here, Nammo’s M72 ASM RC, features a dual-mode warhead that is controlled by a magnetic “switch” on the side of the launcher. When the magnetic switch is in position, a current is induced on a coil wound around the rocket when it is fired via Faraday’s law, which lengthens the delay on the warhead. Alternatively, when the switch is “off”, no current is induced and the warhead defaults to a shorter delay.

The push for programmable munitions is coming in response to many defense trends. Airbursting munitions have long been used to fight aerial targets, and programmable munitions give “flak” capabilities to almost every autocannon, making every IFV more effective against drones. Also, as many militaries look to gear up their armored fighting vehicles for the next generation of peer or near-peer armored warfare, programmable munitions are an easy way to greatly improve the lethality of almost every medium to large caliber gun.